Fukushima Daiichi Nuclear Power Plant

Measures taken by Daishichi because of the accident

All Daishichi’s products are proven to be safe

Immediately after the accident at the Fukushima Daiichi Nuclear Power Plant in 2011, Daishichi took all possible measures to ensure the safety of its products at every stage of the production process. We have had strict measurements taken with a germanium detector by a public research institute, which has officially certified that no radioactive substances have ever been detected. Despite this clean record, as long as worries about products from Fukushima continue, we will go on with our checks for the peace of mind of our customers around the world. The specific measures we have taken are described below.

Location of Daishichi

The Daishichi Sake Brewery is located inland, 60 kilometers from the Fukushima Daiichi Nuclear Power Plant. This is not a directly affected area, but because of the hydrogen explosion in March 2011, radioactive matter was spread over a wide area, including ours.

Emergency measures taken at the time of the accident

As soon as we heard the news about the nuclear accident on March 11, we immediately stopped air conditioners and ventilators and covered the windows and air ducts in plastic sheets to keep the inside of the brewery and storage areas airtight.

In that way, we prevented that radioactive dust and dirt particles hovering in the air could enter the building. The amount of radiation inside the brewery was maintained at the very clean level of 0.04 to 0.06 microsievert, about the same level as normal.

The environment inside the brewery

The Daishichi Sake Brewery is protected by walls of 32 cm thickness, among which 25 cm of concrete. Almost no radiation can penetrate these walls.

We have fitted all openings and doors with high-performance filters and air curtains. The environment inside the brewery is kept very clean.

About the water

Our brewing water comes from a well inside our building called “Naka Ido.” It is not easy for radiation to penetrate the soil, so our brewing water, pumped up from our deep underground well, is safe. Every year we regularly check the brewing water with a germanium detector, and we have never found any radiation matter.

Also, the local tap water comes from a deep well at the foot of Mt Adatara and does not pass through any open water as it is conveyed to the houses in town via subterranean pipes. There has never been any radiation matter detected in it.

About the rice

The rice Daishichi uses as ingredient for sake mainly comes from the Aizu-Wakamatsu area in western Fukushima (Gohyakumangoku sake rice), from Toyama on the Japan Sea coast (Gohyakumangoku sake rice), and from Hyogo Prefecture in Western Japan (Yamada Nishiki sake rice). Since the accident, the Fukushima Prefectural Government checks every single bag of rice produced within its borders – rice from Fukushima is 100% safe. In addition, our company has obtained a NaI scintillation survey meter and we thoroughly check all the rice we use according to the standards set by the Ministry of Health, Labor and Welfare (“Standard Limits for Radio Nuclides in Foods”).

At Daishichi, we do our utmost to guarantee the safety of the rice we use. At the same time, we take care not to foster any harmful rumors. As long as the safety of the rice is completely assured, we do not avoid any particular growing area because of false rumors.

About the bottling

At Daishichi we produce our sake from safe ingredients in a safe process, and we bottle it in a clean environment. Our bottling plant incorporates the first anoxic bottling line in Japan, so that bottling takes place with no contact between the sake and the air outside.

In this way, we do our utmost to guarantee the safety of our products. We are convinced that all our products are safe and recommend that our customers use them without any worry, both at home and as gifts.

The use of safe screw caps

Since 2007, Daishichi is using screw caps of a unique new design. In the case of the type of screw caps generally in use, when opening the bottle, a sharp, metal strip comes off that can hurt the fingers. Thanks to the cooperation of our screw cap maker, we have improved the design so that no metal strip comes off anymore. Instead we have added a shrink seal to indicate that the bottle is still unopened. We are the pioneer among breweries in introducing this new screw cap.

All Daishichi’s products use new bottles

Until recently, Daishichi has been using recyclable bottles for our junmai and honjozo sakes. But as cartons and pet bottles have become more popular, the supply of new bottles to the recycle market by large providers has declined and the quality has quickly fallen off.

Daishichi has therefore decided, in order to guarantee safety, to use new bottles for all its products. We also hope that by supplying new bottles to the market, we will help to maintain the recycling market as much as possible.

Currently, the production of new bottles nationwide is tight, so we may have to temporarily change bottle colors and use recycled bottles. Thank you for your understanding.

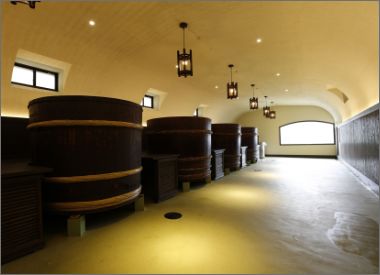

The maintenance of biodiversity by the Kimoto method

For a long time we had been considering that our new brewery should consist of wood (the flooring), earth (diatomaceous earth walls) and stone (the granite of the staircases, etc.). So we completed a structure that insulates us from outside heat and that will stand strong for many centuries. Our sole intention was to provide a pleasant environment to the micro-organisms that thanks to the kimoto method have been living for many years in the Daishichi Sake Brewery. As a result, a rich ecosystem of micro-organisms characteristic of kimoto is thriving in our brewery, including a lactic acid bacteria that carries a specific enzyme that was newly discovered at Daishichi.

Efficient use of rice by the superflat polishing technique

The superflat rice polishing technique, developed in-house by Daishichi, marvelously succeeds in eliminating the rice bran from the thick part of the grains that until now was insufficiently removed by the conventional spherical way of polishing. And yet Daishichi’s polishing ratio for top class sake basically does not have to go further than 50%.

Daishichi’s “superflat rice polishing technique” allows us to reach a quality level that is impossible by conventional polishing, and that also makes the most efficient use of the precious rice. That is why in 2014 Daishichi was awarded the Special Prize of the Jury President of the 11th Eco Products Awards. Our technology was also introduced to the world by the NHK International Program as an innovation of which the nation is proud.

Efforts towards organic cultivation

For almost a quarter century, from 1992 to 2015, with our employees Daishichi has grown organic sake rice at a field in Nihonmatsu. This started from the wish of our employees (who seldom have a farming background) to learn more about the rice used in sake brewing, and it proved to be a good education for all of us.

We called our field “Mutenden,” in the sense that “even the sky is not the limit.” We enjoyed the rice planting and harvesting together with a group of Daishichi fans who came from Tokyo to help us. This beautiful field suffered from the accident at the Fukushima Daiichi Nuclear Power Plant caused by the 2011 Tohoku earthquake and tsunami, so all our employees worked hard to remove the top soil for decontamination and plant soy beans to bring new nutrients to the remaining soil. Four years after the disaster, we for the last time planted rice here, making sure that we had given new life to our field. Thereby ended for the time being the long challenge of cultivating part of our rice.

The installation of solar panels and LED lights

Daishichi has installed solar panels on the roof of our rice polishing plant. With an annual power generation capacity of 40,000 kilowatt, we can cover 30% of the electricity we need for rice polishing. We have also changed the mercury lamps hanging on the high ceiling in our plant into LED lights, saving one third of the electricity we need for lighting. At Daishichi we have changed all the lights in our company into LED lights. In energy and resource saving we are a model company.

Plastic free - Corrugated cardboard material for cushioning

Daishichi is always interested in initiatives to reduce environmental impact. For a long time we wanted to stop using Styrofoam as a cushioning material for our high-end products. However, we were unable to find a material that could replace Styrofoam in terms of functionality, appearance and cost, while also protecting our products for export overseas. Then, Dynapac, a manufacturer of packaging materials, came forward for joint development. Through repeated trial production and test runs with delivery trucks, we were able to determine the durability of the material and that the labels of the bottles would not be damaged. The cushioning material made of corrugated cardboard has a threedimensional double-door shape that holds the bottle firmly in place and, when unfolded, forms a single sheet that can be easily bundled for recycling. In this way Daishichi has been able to reduce a total of approximately 2,200 kg of plastic per year.