Super-flat Rice Polishing

A unique rice polishing technique that polishes away the same thickness from each surface of the brown rice. It removes the proteins concentrated near the surface of the rice to a level and with an efficiency never seen before, while the required starch remains.

Why sake brewing requires

rice polishing

The rice germ and outer husk contain large amounts of proteins, oils, minerals and vitamins. These compounds change the balance of the fermentation by accelerating the growth of koji mold and yeast. They also degrade the quality of the sake by causing tinting and unwanted flavors. The purpose of the rice polishing process is to remove such elements. But it is not a matter simply of “the more polishing the better.” A high degree of polishing results in a delicately-flavored sake such as daiginjo. A medium degree of polishing will result in a sake such as junmai, which has a robust richness that makes it perfect for drinking warm. So variations in rice polishing translate into a rich variety of sake types, and polishing is a vital factor in the final flavor.

Problems with conventional

rice polishing techniques

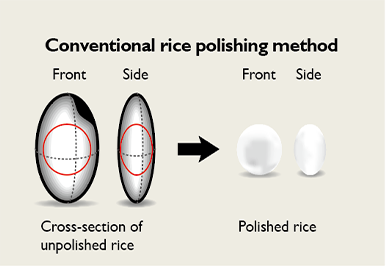

The most widespread polishing method seeks to polish rice as quickly as possible by increasing the rotational speed of the rice-polishing machine roller (whetstone). At the same time the density of rice in the polishing chamber is lowered to prevent cracks and splits. This makes the grains far more likely to rotate wildly on their short axis, leading to more polishing action being applied to the ends of the long axis of a grain. This results in spherical grains.

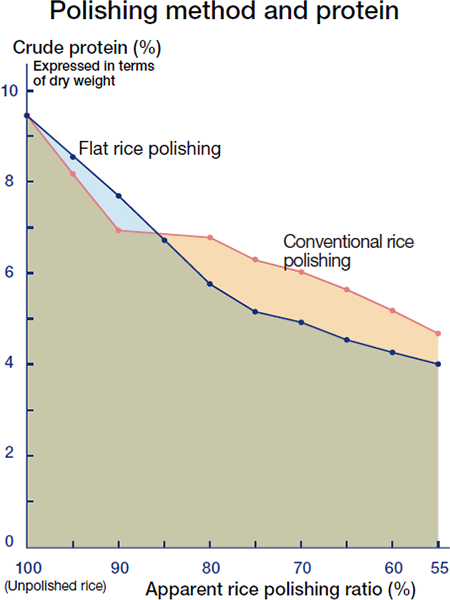

As a result, the rice is polished to an extreme degree at the ends of its long axis, while the shorter, stouter axis is barely touched. The outcome is that the conventional polishing technique leaves behind undesirable elements on the short axis, and wastes precious starch on the long axis. (See chart on rightbelow)

The solution: flat rice polishing

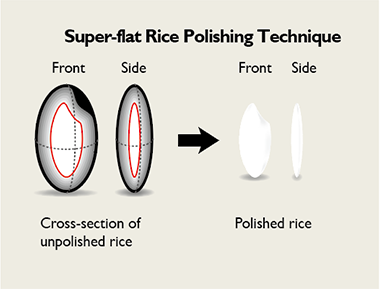

As a way to overcome these defects, Tomio Saito and others proposed the flat rice polishing technique. This method aims to polish away the same thickness from each surface, resulting in a flatter rice than with previous methods.

It is clear from the diagram on the rightbelow that unwanted parts are completely removed while the required starch remains.

(For this method Mr Tomio Saito received the “Award of Merit” of the Brewing Society of Japan.)

The principle of the flat rice polishing technique can be seen in the animation below. With slow rotation of the rice-polishing machine roller (whetstone), and a high density of rice in the polishing chamber, the rice will rotate on its longer axis, resulting in long, thin grains.

However this method requires much more time to polish rice than the conventional method, and presents a far greater risk of cracked grains.

A simple benchmark:

the flat rice polishing ratio

So what is a rice polishing ratio? The equation “weight of polished rice divided by weight of unpolished rice times 100 (%)” only gives the percentage of polished rice yielded from unpolished rice and, at the same time, the percentage of unpolished rice discarded as bran. It does not tell us how efficient the rice polishing has been.

We recommend a new approach: adopt as benchmark the removal of unwanted elements from a rice grain’s thickness along the short axis, which is the hardest part to polish by traditional methods. This gives us the flat rice polishing ratio.

Flat rice polishing ratio (%) = (Thickness of polished rice/Thickness of unpolished rice)³ x 100

The easiest part of a rice grain to polish is its length, then its width and, finally, polishing the thick part in the middle is the most difficult. So if a calculation of volume can be made based on how much of the thickness – the most difficult part to polish – has been removed, it is possible to estimate that a greater amount of unwanted material has been polished from the length and width. It would therefore have to be considered equal or superior to rice polished to the same ratio in the shape of the grain.

Daishichi’s super-flat rice

polishing technique

Daishichi has always been very interested in the flat rice polishing theory proposed by Tomio Saito and has worked hard to implement it in practice. In order to make the benefits of flat rice polishing clear, and to overcome the challenges this method has encountered – cracked grains, as well as the extra time and labor the process requires – Daishichi has performed innumerable polishing tests, ultimately succeeding in establishing the most efficient flat rice polishing technique to date. As it surpassed the assumptions of its inventor, Mr Tomio Saito, we have named our polishing technique “super-flat rice polishing.”

polishing technique

polishing techniques

In the case of conventional rice polishing, at whatever polishing ratio, the apparent polishing ratio normally is smaller than the flat polishing ratio. But because the grains become spherical, the stouter part is not sufficiently polished. As a result, the bran is not removed as much as the polishing seems to show.

In contrast, in the case of Daishichi’s super-flat rice polishing, with a flat rice polishing ratio of 51.3% when the apparent rice polishing ratio is 70%, the quality is overwhelmingly better. It is also possible to reach a flat polishing ratio of 34% with an apparent polishing ratio of 51% (in the case of conventional polishing the result is much worse, as the flat polishing ratio becomes 64.4% at an apparent polishing ratio of 35%).

| Apparent rice polishing rato |

Flat rice polishing raito |

|---|---|

| Unpolished rice | |

| 90 | 71.5 |

| 80 | 64.1 |

| 75 | 53.7 |

| 70 | 51.3 |

| 63 | 44.4 |

| 58 | 36.8 |

| 51 | 34.0 |

in the case of Daishichi's superlfat rice polishing.

Quality of completed rice

A comparison of analyses of super-flat polished rice and conventionally polished rice demonstrates that super-flat rice polishing is extremely efficient at removing the large amount of proteins near the surface of rice grains, and that it is an enormously effective polishing method. 70% super-flat-polished rice (apparent polishing ratio) and 58% conventionally-polished rice (apparent polishing ratio) contain the same amount of remaining protein. This means that simply using the super-flat polishing method achieves the same result as improving the conventional polishing ratio by 12%.

| Sample | Flat rice polishing raito |

Shape | Residual crude protein |

|---|---|---|---|

| Competitor 35% Yamada Nishiki |

64.4% | Spherical | 51.55% |

| Daishichi 58% Gohyaku Mangoku |

36.8% | Super-flat | 44.07% |

| Daishichi 51% Yamada Nishiki |

34.0% | Super-flat | 44.32% |

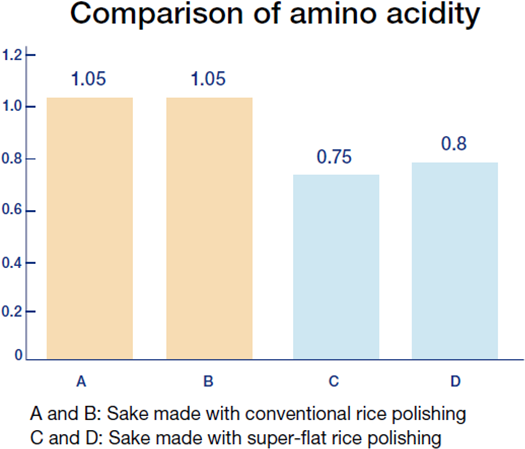

Quality of completed sake

An actual brewing test was performed by making sake with rice of the same apparent polishing ratio, polished by both the super-flat technique and the conventional method. The rice polished with the super-flat technique resulted in a beautiful, clean-tasting ginjo sake, low in amino acids. This is also clearly reflected in the tasting results. On a 4-point assessment, with 1 being the highest rating, sake made from conventionally polished rice received an average of 2.45, while super-flat polished rice-derived sake received a 1.65.(This is the average of the points given by each judge, with 1: very good, 2: good, 3: average, 4: problematic. The lower the average, the better)Also, when the test samples were deliberately exposed to sunlight, then tasted, the sake made from super-flat-polished rice had barely a hint of “light-struck flavor” degradation, revealing a substantial preservation margin compared to sake made from conventionally polished rice.

Thoughts on recent extreme polishing ratios

The conventional polishing method that results in spherical grains is inefficient. Even if these spherical grains are made extremely small, can they reach the same quality as rice polished with the super-flat method?

No, we don’t think so. Our way of thinking about rice is different.

Daishichi has a preference for good sake rice (shuzo kotekimai), which has a white, opaque, soft center, the so-called “white heart” (shinpaku). This shinpaku is responsible for the beautiful, soft umami of the sake. But as the shinpaku has a soft and fragile structure, the grain will break when the rice polishing reaches this part. Daishichi’s super-flat rice polishing technique takes great care not to break the shinpaku and skillfully makes use of it.

But the fragile shinpaku forms an obstacle when polishing the rice to an extremely small size. Ironically, it is more convenient therefore to use rice without shinpaku.

Daishichi’s philosophy is to have the highest respect for the rice and to bring out all its qualities. It is not possible to obtain the supreme enjoyment of umami by extreme polishing.

Daishichi’s rice polishing ratio is a basic super-flat polishing ratio of 50% even in the case of our highest class sakes. We are convinced that rice of a pure and superb quality is obtained by that method, and not by making the rice as small as possible.

History of Super-flat Rice Polishing

In 1993, we started developing flat rice polishing, and in 1995, for the first time in Japan, we succeeded in the practical application of the "super-flat rice polishing" technology, which surpassed the concept of flat polishing. Below follows a detailed history of "super-flat rice polishing." For all Daishichi’s sakes, from Honjozo sake (regular sake) to the highest peak undiluted Junmai Daiginjo obtained by natural drip, super-flat polished rice from our own polishing plant is used.

- 1993:

- Start of Flat Rice Polishing

Tomio Saito, head of the Tokyo Regional Taxation Bureau's Appraisal Office, wrote the first two papers on flat rice polishing in the Journal of the Brewing Society of Japan (in the January issue "Evaluation of White Rice for Sake Brewing Using the Sieving Method,” and in the March issue "Shape and Polishing Efficiency of White Rice for Sake Brewing"). Daishichi Sake Brewery, which took note of these papers, immediately contacted Mr. Saito and started to study the feasibility of flat rice polishing. However, at the time, manufacturers of rice polishing machines had a negative attitude towards flat rice polishing due to the high risk of broken rice. In September, Daishichi Sake Brewery started to try out flat rice polishing on its own, without any help from rice polishing machine makers. - 1994:

- During the second year, the practical application of flat rice polishing is in sight

In 1994, in the second year after we started trying out flat rice polishing, the Daishichi Sake Brewery was on the verge of the practical application of the process, and in December, we began brewing the first Junmai Daiginjo in Japan made with flat polished rice. - 1995:

- Daishichi's technology is named "Super-flat Rice Polishing”

In February, President Hideharu Ohta and Yoshio Ogata, Head of Rice Polishing, visited the Akita Prefectural Brewing Institute, where Mr. Saito had obtained experimental data on flat rice polishing. They observed the flat rice polishing implemented there and confirmed that Daishichi's flat polished rice was clearly more flattened. Their confidence was strengthened. Daishichi's technology was therefore named "Super-flat Rice Polishing," as it was clearly superior to the existing flat polished rice. - 1995:

- Japan’s first Junmai Daiginjo made with the super-flat rice polishing technique is released

In July, the first Junmai Daiginjo in Japan made with super-flat polished rice went on sale as "Minowamon." - 1997:

- For a further leap forward, comparative test brewing is conducted

During the autumn brewing season, super-flat rice polishing was taken to the next level. Daishichi decided to hold a presentation on the results of the super-flat rice polishing technique in the following year. A comparative test brewing of Junmai Ginjo was conducted in order to prepare the data. - 1998:

- The presentation of Daishichi’s research becomes a sensation in the sake world

On April 16, 1998, Keiko Okuda, Head of Daishichi’s laboratory, gave a presentation at the 1998 Sake Brewing Technology Research Presentation Meeting of the Tohoku Branch of the Japan Sake Makers Association in Sendai. On May 22, a presentation of the results was held at the Keio Plaza Hotel. Participants included Mr. Tomio Saito, members of the media, Mr. Shoichiro Yamamoto, Mr. Jiro Shinoda and other sake critics, as well as Mr. Katsumi Kimura, Principal of the Japan Sommelier School, wholesalers, sake retailers, and other industry professionals. In the October issue of the Journal of the Brewing Society of Japan, Mr Tomio Saito's article cited our presentation material. - 1999:

- Award from the Director-General of the Science and Technology Agency

Mr. Yoshio Ogata, Head of Rice Polishing, received the "Award of the Director-General of the Science and Technology Agency" in recognition of his achievement of the first practical application of superflat rice polishing in Japan. From this year, super-flat polished rice, which was originally only used for "Minowamon" and "Kaiden", was expanded to all products, including "Horeki." - 2000:

- Excellent Technician Award of Fukushima Prefecture “Fukushima Master Craftsman”

Yoshio Ogata, Head of Rice Polishing, was awarded the "Fukushima Master Craftsman" award by Fukushima Prefecture. - 2003:

- Brewing Technician Award from the Brewing Society of Japan

Yoshio Ogata, Head of Rice Polishing, received the Brewing Technician Award from the Brewing Society of Japan. - 2008:

- "Contemporary Master Craftsman" Award

Yoshio Ogata, Head of Rice Polishing, received the "Contemporary Master Craftsman" Award for his outstanding skills. This was the first "Contemporary Master Craftsman" Award in the field of rice polishing. - 2014:

- Social Products Award

In March, Daishichi received the “Social Products Award” at the Social Products Awards 2014. - 2014:

- Research report published in academic journal

An article titled "Flat Rice Polishing Method and Sake" by Keiko Okuda, Head of Daishichi’s laboratory, was published in Volume 58 of the Journal of the Society of Abrasive Grain Processing. - 2014:

- Special Prize of the Jury President at the 11th Eco Products Awards

In December, Daishichi received the Special Prize of the Jury President at the 11th Eco-Products Awards. - 2016:

- Tomio Saito, the inventor of the method, received the Distinguished Achievement Award from the Brewing Society of Japan

In October, Tomio Saito received the Distinguished Achievement Award from the Brewing Society of Japan. “I won the award because Daishichi Sake Brewery proved my theory correct," he mentioned. - 2018:

- The Prize of the Minister of Economic Affairs of the “Seventh Monozukuri Japan Awards.”

At the “Seventh Monozukuri Japan Awards,” the Prize of the Minister of Economic Affairs was awarded because of “the development of top class sake by using the super-flat rice polishing technique and the Kimoto method, as well as the development of overseas markets.” The highest prize ever given at this ceremony to a sake brewery.